As a common ingredient on the table, the safety of poultry eggs has always affected the hearts of the public. And veterinary drug residues are one of the important hidden dangers affecting the safety of poultry eggs - excessive use of antibiotics, hormones and other veterinary drugs may not only lead to excessive drugs in poultry eggs, but also threaten consumer health. The traditional method of detecting veterinary drug residues in poultry eggs often takes several days, from sample collection to laboratory analysis, and the long wait not only affects the detection efficiency, but also may delay the handling of the problem. How to quickly and accurately screen for veterinary drug residues in poultry eggs? Today, I will introduce a set of practical solutions for rapid detection of veterinary drug residues in poultry eggs with "results in ten minutes".

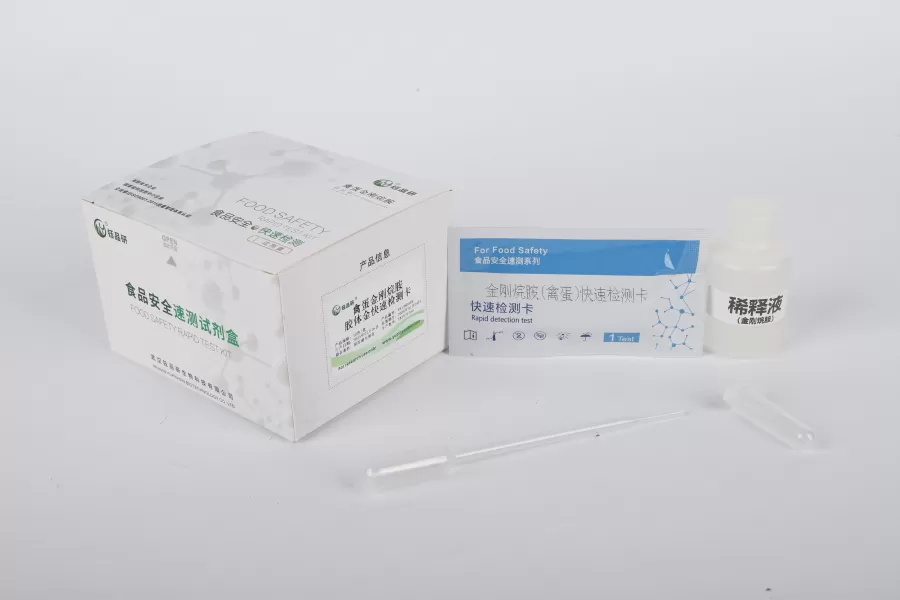

The core of this solution lies in the use of "colloidal gold immunochromatography technology" to achieve qualitative screening of common veterinary drug residues through a special rapid detection test strip. The operation process is simple and easy to understand, and no professional laboratory equipment is required. Grassroots inspectors, farm self-inspectors or market supervisors can quickly get started. The specific steps include: sample pre-processing (take a small amount of egg liquid or egg yolk, add the extract to concussion centrifugation), test strip testing (drop the treated sample liquid into the test strip and add the sample hole, and wait for ten minutes), and result interpretation (determine whether there is residue according to the quality control line on the test strip and the color development of the test line). The whole process from sample processing to result presentation, the whole process does not exceed half an hour, and truly realizes "fast results".

Why can this program achieve "ten minutes"? The key lies in its highly integrated detection principle: the test strip is pre-coated with monoclonal antibodies against specific veterinary drugs (such as tetracyclines, sulfonamides, and floxacins, etc.). When there is a target veterinary drug residue in the sample, it will bind with the antibody to form a complex. Under the chromatography of the test strip, it will bind to the antigen on the detection line, and finally develop color under the combined action of the quality control line and the detection line. If the detection line shows color, it indicates that there are such veterinary drug residues in the sample; otherwise, it is negative. Although it is a rapid detection, the program ensures the accuracy of the test results by optimizing the specificity of antibodies and reaction conditions. Its sensitivity can reach more than 90% of the national standard, which can effectively avoid missed or false detection.

In practical applications, the advantages of this program are very prominent: for farms, it can monitor the use of veterinary drugs in the production process of poultry eggs in real time, adjust the medication plan in time, and reduce the risk of residues from the source; for market supervision departments, it can quickly screen unqualified eggs in the circulation link to reduce the sampling cycle; for food processing enterprises, it can quickly verify the safety of raw eggs and avoid production accidents caused by excessive residues.

It is worth noting that although the rapid detection scheme is convenient and efficient, it is still necessary to choose test strips certified by authoritative organizations to ensure the quality of the detection reagents. At the same time, if the test result is positive, it needs to be quantitatively reviewed by laboratory methods such as high-performance liquid chromatography to ensure the rigor of the data.

The safety of poultry eggs is no small matter, and the progress of rapid detection technology provides a strong support for guarding the "safety on the tip of the tongue". This "ten-minute result" rapid detection scheme for veterinary drug residues in poultry eggs is becoming an important tool for the safety supervision of poultry eggs because of its convenience, efficiency and practicality. Whether it is professional inspectors or ordinary consumers, understanding and making good use of such technologies can add another line of defense to the safety of poultry eggs.